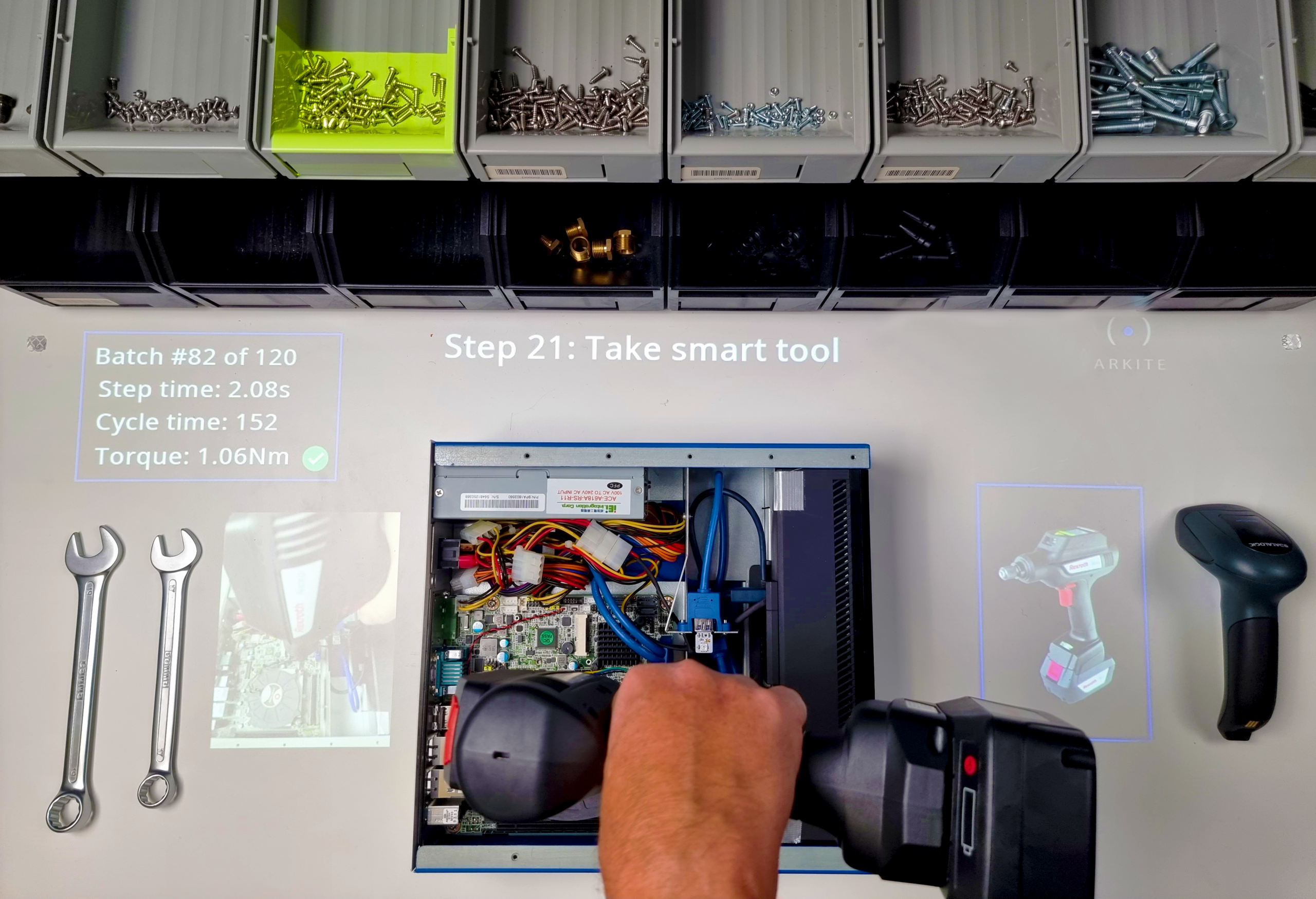

Guiding your work with augmented reality.

Arkite Industries

success for addressing manufacturing challenges in your industry today.

Arkite Solutions

Arkite platform

Arkite’s Approach

Arkite platform

The most user friendly operator guidance system in the world

Discover how we can help you in providing digital work instructions to your operators and validate their correct execution.

One platform for all your

manufacturing operations

Arkite transforms workstations into a digital and interactive environment by:

- Guiding your operator with Augmented Reality instructions

- Validating your operations with our embedded smart-sensor

- Inspecting your products with our fully integrated VISION package

- Integrating your eco system to create smarter workstations

- Converting your manual operations into knowledgeable information

Tackle today’s challenges in manufacturing with Arkite’s Operator Guidance platform

Explore the details of our solutions here:

Guiding your work with Augmented Reality

Manufacturers across the globe have been making important investments in the automation of their manufacturing plants. These smart factories are getting equipped with advanced sensors, embedded software and robotics, while collecting and analyzing relevant data for better decision making. Despite this continuous drive for further automatization, manual workstations will remain essential in most manufacturing plants. At Arkite we recognize that these workbenches also deserve a major upgrade as current practices are often based on outdated technologies, substantially hampering desired efficiency – and quality improvements.

Deploying AR in the Automotive Industry

The present-day automotive industry is characterized by significant innovation as diverse mobility, autonomous driving, electrification and connectivity are shaping this industry for the next decade. These disruptive trends are giving rise to intense competition that is undermining existing brand strategies, while at the same time presenting huge opportunities for these existing manufacturers, new brands and automotive suppliers alike.

Arkite’s Operator Guidance platform transforms your manual workstations into a digital environment by deploying Augmented Reality. It will give you the control and insights to efficiently steer and optimize your manual assembly processes.

Arkite’s operator guidance platform

- Smart by providing intelligent detections and process steps.

- Integrated with the factory IT Systems

- Contactless and easy to install, configure, use, maintain, adapt and scale…

These companies are already using our platfrom.

Arkite’s Integrated Smart Vision

With our brand new Arkite VISION plan, an additional high definition vision sensor is added into the Arkite platform.

The Arkite software will then be able to perform quality inspection during the assembly and provide immediate feedback. It will detect whether small screws and bolts (>0,5 cm) are present and assembled in the right orientation.

Improve your

manual operations

with better

consistency

and reliability

%

error reduction

%

rework reduction

%

reduce training time

Learn more about Arkite

Is Projected AR the Answer to Your Manufacturing Challenges?

In a rapidly evolving manufacturing landscape, staying ahead means embracing cutting-edge technology. Arkite’s latest ebook, “Is Projected AR the Answer to Your Manufacturing Challenges?” offers an insightful exploration

5 challenges in production and how to solve them

In the dynamic world of manufacturing, challenges are as constant as change itself. But what if you could turn these challenges into opportunities? “5 Challenges in Production and How to Solve Them” is your guide to doing just that.

Finished – Unveiling Arkite VISION – Elevating manufacturing with revolutionary software

Why Attend? •Gain firsthand insights into the cutting-edge technology reshaping industrial manufacturing. •Discover how Arkite VISION can elevate your production processes, enhance product quality, and increase efficiency. •Interact with experts and get your questions...